Avery Dennison leads digital sign transformation

First published in Intertraffic Innovation News - June 30, 2020

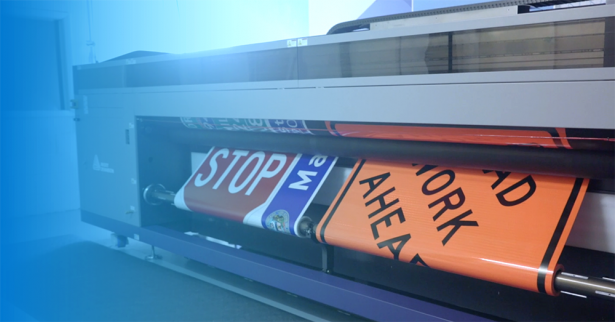

The traffic sign industry has come a long way from wood-painted signs to today’s retro-reflective prismatic signs. With improved sheeting performance, the industry has also experienced a positive production transformation, moving away from traditional screen printing and computer-cut methods to digital printing. While many sign shops are already fully digital, large high-volume sign shops have been slower to make the switch because screen printing was consistently faster and more economical for production.

The traffic sign industry has come a long way from wood-painted signs to today’s retro-reflective prismatic signs. With improved sheeting performance, the industry has also experienced a positive production transformation, moving away from traditional screen printing and computer-cut methods to digital printing. While many sign shops are already fully digital, large high-volume sign shops have been slower to make the switch because screen printing was consistently faster and more economical for production.

The smell from screen printing has been a persistent problem for shop operators across the globe and poses significant environmental hazards that require immediate attention. Aaron Means, Avery Dennison senior product manager, explains, “Digital sign shops do not expose their workforce to the hazards associated with screen printing. Operators are working in a cleaner, safer workplace with the TrafficJet Print System. It was important that the next generation of digital traffic sign printing could challenge the need for screen printing in traffic sign shops in both speed and cost. We’ve done that with TrafficJet Pro.”

The new TrafficJet Pro delivers print speeds that can replace screen printing at 680 ft2 (63 m2) per hour. Not only do operators avoid the screen printing fumes, but they also have a much cleaner and simpler maintenance process that doesn’t cause any water waste. With support provided by Avery Dennison, operators can confidently rely on one single point of contact for printer servicing, digital inks, and sheeting, giving them the peace of mind as they transform their production to go digital.

Companies in this article

Avery Dennison