Formolight smartens up VMS maintenance

First published at ITS World Congress - October 23, 2019

Faster light replacements and shorter lane closures for variable message signs are advantages of using a wireless smart maintenance process from Taiwanese firm FormoLight.

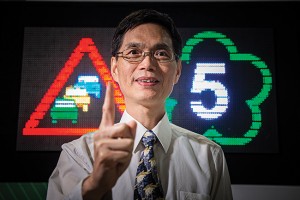

The standard procedure for repairing broken variable message sign (VMS) units is to send two maintenance people out to site, then close a lane during inspection and replacement of parts, explains Jonson Lin, FormoLight vice president.

With the lane closed, one worker has to climb up to replace the faulty light unit within the larger VMS system. During replacement, another worker will have to be at ground level to liaise with the one above to ensure correct and uniform brightness of the VMS. Now Formolight’s wireless system means that brightness can be adjusted wirelessly with a single worker standing at ground level below the VMS.

Once the VMS hardware has been adjusted, the same worker can then use the wireless system to adjust the brightness and colour levels – and do this with the lane open and the worker standing safely beside the road.

Mobile, temporary and permanent VMSs from FormoLight are manufactured to European Standard EN12966. They feature 10, 15, 2025, 30 or 57.2mm pixel pitch and meet international protocols such as RTA,

Booth 232

Companies in this article

Formolight