Berco’s ROBUSTUS boosts robustness of dozer undercarriages

First published in bauma Preview - March 20, 2019

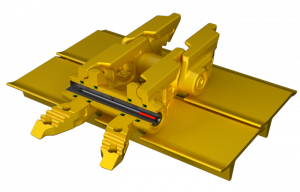

The ROBUSTUS from Berco that includes the Berco pin retention system lowers dozer undercarriage wear and improves operator comfort.

The concept is based on a concept where the bushing fully rotates around the sprocket, according to the Italian company which is part of the Thyssenkrupp group and a major first tier supplier of undercarriages to global construction equipment manufacturers.

ROBUSTUS – ROtating BUShing Track Undercarriage System – allows the bushing to rotate separately from the linkage system to dramatically lower wear of the bushing and sprocket. The system requires the Berco pin retention system, reinforced bolts and nuts and improved seal design. The resulting increased stability translates into more comfort for the operator because of less noise and fewer vibrations.

The company estimates that undercarriage lifetime can be extended up around 35%, with up to 6,000 hours of dozer operation with no maintenance. This could translate into a cost saving of 25%. ROBUSTUS us recommended for highly abrasive soil conditions.

Companies in this article

Berco

Product Launch Videos

Most popular news

- Fayat’s forward view – at bauma 2019

April 16, 2019 - Hitachi’s ZX65USB-6 mini excavator works harder with less fuel

April 15, 2019 - Komatsu boost fuel efficiency with its WA475-10 wheel loader

April 15, 2019 - Smiley Monroe launches conveyor belt page turner at bauma 2019

April 12, 2019 - Topcon’s sophisticated head-up display goes on show at bauma 2019

April 12, 2019 - Liebherr’s innovative piling rigs at bauma 2019

April 12, 2019